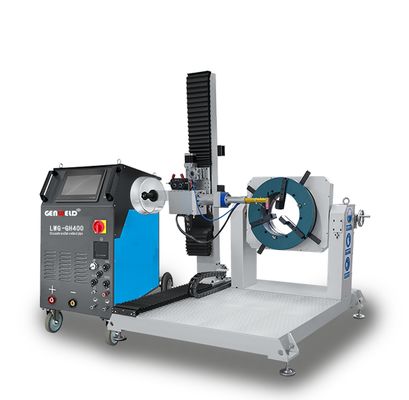

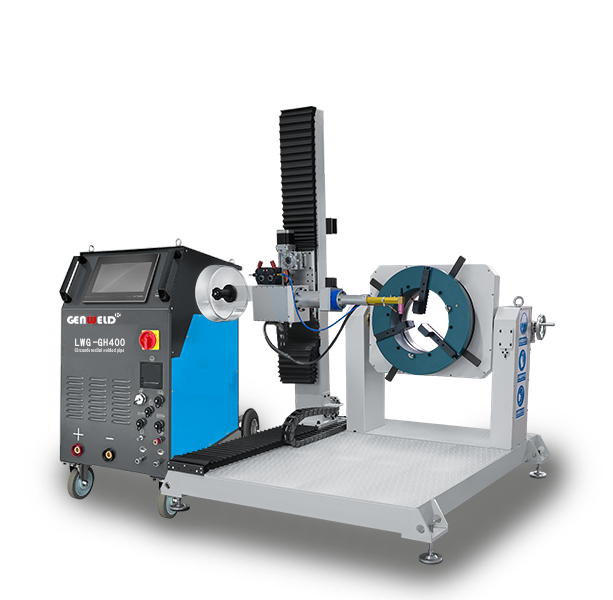

LWG-GH400 Automatic Circumferential Welding Equipment(Pipe Welding Machine Series)

Product Details:

| Place of Origin: | Chongqing, China |

| Brand Name: | GENWELD |

| Certification: | ISO9001 |

| Model Number: | LWG-GH400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 |

|---|---|

| Packaging Details: | 2500×1000×1500 |

| Delivery Time: | 2-7 works days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30units/per month |

|

Detail Information |

Product Description

Equipment Overview

Composed of an LWG-GH400 power supply and an LWG-GH400 automatic circumferential welding machine frame, this equipment employs TIG welding technology, allowing for filler wire or autofusion welding. It is primarily used for welding circumferential welds (including root pass, filler pass, and cap pass), and is an essential welding process equipment for the production of various pipes and fittings.

It is mainly used for circumferential welding of cylinders, tees, elbows, pipe flanges, etc., as well as lap joint welding of cylinders. It is widely used in industries such as petrochemicals, medical machinery, instrumentation, and environmental protection equipment.

Power Supply Introduction

This 400A welding power supply integrates the welding machine core, control module, arc voltage tracking, welding torch oscillation, integrated wire feed, circulating cooling water tank, printer module, IoT module, and USB download interface into a single hardware and program control unit.

It incorporates a pipe welding database, automatically generating all necessary welding parameters based on user-inputted pipe diameter, wall thickness, and other information, making it truly simple and easy to use!

Equipment Advantages

1. High Level of Intelligence: In addition to the welding core, cooling system, and PLC, the welding power supply unit also integrates USB (for convenient uploading and downloading of welding data), I/O detection function (for real-time monitoring of the operating status of each component), and an IoT module (for remotely upgrading the control program or resolving faults caused by improper operation, and for networking to achieve a smart factory).

2. Simple to Use: Controlled by a Siemens PLC and combined with a welding database (integrating 900 sets of welding parameters), users only need to assemble the pipe fittings, clamp them, align the welding torch, and press the start button to complete the welding.

3. Easier Pipe Fitting Formation: The 400A arc welding power supply, through adjustments to the pre-melting current, pre-melting time, welding current, welding time, and base current and base time, combined with the PLC-controlled wire feed speed, rotation speed, oscillation width, and arc voltage matching, makes it easier to achieve full penetration and formation of the root pass, and the cap weld is more delicate and full, meeting the user's radiographic requirements.

4. Faster Welding Efficiency: No hot wire or flux is required. Its self-developed wire feeding module can feed 1.6mm welding wire, making it 30% faster than similar welding equipment on the market when welding pipes with a thickness of 5-18mm.

5. Enhanced Safety: Abandoning traditional high-frequency arc ignition, it adopts passive arc ignition technology, minimizing harm to the human body during high-current welding. Furthermore, the welding machine is equipped with overvoltage, overload, and tungsten inert gas (TIG) short-circuit alarm functions.

Equipment Application Scope and Process Requirements:

1. Workpiece Specifications:

This equipment is suitable for butt welds or fillet welds of pipe fittings, and circumferential welds of round workpieces with a diameter ≤600mm. Examples: straight pipe to straight pipe, straight pipe to elbow, straight pipe to tee, straight pipe to flange.

1.Workpiece Diameter Range: Outer diameter 20mm-600mm; (chuck can hold 20-600mm, through hole 350mm) ,

2. Workpiece Length Range:20mm-6000mm, frame can be customized (extra-long pipe fittings require external support);

3. Maximum Workpiece Weight:500 kg

4. Workpiece Pre-Welding Condition: Surface free of oil, rust, and coatings;

5. Working Environment Temperature/Relative Humidity: -10°C~50/90% non-condensing

2. Workpiece Assembly Requirements:

The welding end face of the workpiece is processed using a dedicated beveling machine, and the joint must be regular and uniform; workpieces thicker than 3mm require a V-groove. Ensure that the weld joints of the workpieces are flush, remove burrs, and ensure that the assembly gap meets the welding requirements. The assembly gap should be less than 2% of the thickness of the blunt edge wall. Pre-weld the workpieces before welding, and the tack welds should not be too large (it is recommended to use TIG welding for tack welding teams). Clean the contaminants in the joint area.

Want to Know more details about this product